|

What Pottery Supplies and Tools do Potters use?Potters use quite a variety of handmade and purchased Pottery Supplies and Tools. Of course the Potter's primary tools are their hands. However during the long History of Pottery making, a variety of tools have been developed. The arsenal of Tools includes:

After the initial outlay for the big ticket items such as a wheel, kiln, and some tools; the ongoing pottery supplies needed revolve mostly around the clay and glaze components. Clay refers to a group of minerals that when mixed with water, basically demonstrate the characteristic of plasticity (ability to change shape when a force is applied). Clay primarily is composed of alumina and silica. Clay Bodies are combinations of clays mixed with other minerals such as feldspar, grog (fired and ground clay added in to stabilize the firing), quartz, flint, spodumene, wollastonite, and more. These mixtures or clay bodies can be formulated to fire at a wide range of temperatures depending on the affect the Potter is trying to achieve. Clays that appear darker typically contain iron and other metal oxide components. Porcelain and white stoneware generally contain much less impurities.

One of our resident Pottery Experts, Dennis Maza of New Jersey, maintains a book of custom clay formulas that he likes. Dennis explains the importance of curing the clay bodies after mixing up the proper proportions of for example, Pine Lake Fire Clay - Double X sagger, Gold Art, Red Art, Feldspar, Fine Grog. After mixing these pottery supplies all together, you usually give it at least 2 months to sit and cure. This is known as "Curing the Body". This allows the water molecules to surround each particle of the clay components. Without this curing period you will end up with inconsistent results. Different types of clay, when used with different minerals and firing conditions, are used to produce earthenware, stoneware, and porcelain. Clay Types Kaolin or Kaolinite is a layered silicate mineral. Rocks that are rich in kaolin are known as china clay, white clay, or kaolin. The name kaolin comes from Kao-Ling or High Hill in the Jiangxi province of China. It is a very common mineral and is mined as kaolin in Brazil, France, UK, Germany, India, China, Czech Republic, and the U.S. Kaolin is a soft usually white mineral produced through weathering of minerals such as feldspar. Ball Clay is a sedimentary clay that commonly consists of:

Due to the nature of the sedimentary layer from which Ball Clay comes, the composition varies. However, Ball Clay is typically characterized by its fine grain and plasticity. Ball Clay is relatively scarce. It is mined in the Eastern United States, as well as several places in Western England. Ball Clay is a pottery supply used to provide plasticity and to avoid unintended deformation during the shaping process. Pottery Wheel Often a disk of plastic, wood, or plaster is first placed on the wheel-head. This disk is called a "bat". The ball of clay is then placed on top of the bat so that after the forming of the clay is complete, the finished piece can be removed intact with its bat, without distorting the piece. Electric wheels are great for producing pieces relatively quickly. They are usually lighter than kick wheels, and can be transported easier e.g. to other Studios, or an Arts Festival. Some of the biggest name brands in electric Pottery Wheels are: Amaco - Brent pottery wheel, Shimpo, and Pacifica. Typical costs for pottery wheels range $800-$1400. Kick wheels are very low maintenance and will usually last for many decades. Often they are used for trimming and decorating. Common brands for kick wheels are: Thomas Stuart and Brent. Prices for Kick wheels range $500-$1500.

Here we have one of our favorite pottery artists, Deborah Slahta, working her magic on the pottery wheel.

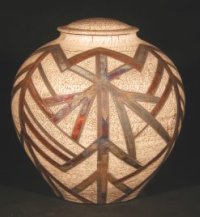

She turns out beautiful Raku fired vases such as this one.

Check out some of

Deborah Slahta's other work here.

Find out more about the Pottery Wheel and see a video of Deborah in action on our Pottery Wheel page.

Among the smaller and lower cost pottery supplies and tools are the... Shaping Tools Pottery supplies commonly used for shaping include:

Rolling Tools Pottery supplies commonly used for Rolling include:

Cutting or Piercing Tools Pottery supplies commonly used for Cutting or Piercing include:

Finishing Tools Pottery supplies commonly used for Finishing include:

Pottery Glazes When it comes to pottery supplies used to coat, color, preserve, or otherwise leave the Artist's signature finish, the all important Glaze enters the picture. In short, Pottery Glazes are made up of 5 basic components:

Glazes come in a very large range of colors. Common pottery supplies used as colorants are: copper oxide, copper carbonate, chromium oxide, cobalt oxide, and iron oxide. The end color result on the pottery is also determined by factors such as the amount of oxygen in the kiln at the time of firing. Also affecting the end color result are the base color of the clay as well as any previously applied layers of glaze (underglaze), as these multi layerings will mix and create differing colors. We'll talk more about Glazes and some of our favorite recipes on our Glaze page (coming soon to a browser near you). Pottery Kiln (pronounced "kill") Essentially insulated furnaces with temperature controls, Kilns represent the largest pottery supply and tool investment for the Potter. They are intermittent heaters in that they gradually increase in temperature, then after a period of time, they go through a cooling period. Kilns generally come with several options:

|

Appreciate when you ...

What's New on BH?

Blog: Old Fourth Ward - Atlanta, GA

Feature: Potter - Julie Jones

Store: Paintings by Carol Benner

Editor Picks from Store

|

|

|

| Lavender Painted Soap | Volcano Dangle Earrings | Footed Coffee Mug |